The synergy between biology, technology and innovation has paved the way for notable possibilities when it comes to modern medicine – and 3D bioprinting is at the heart of this revolution. Nowadays, human tissues, organs as well as complex biological items are produced according to this technology on the international scale.

In India, 3D bioprinting is fast catching up traction as research institutions, startups and healthcare bodies have recognized at least some potential applications in the country in order to re-shape the future of healthcare, regenerative medicine and even drugs testing.

This article goes in to the basics of how 3D bioprinting works, its application and developments in India in this revolutionary field.

What Is 3D Bioprinting?

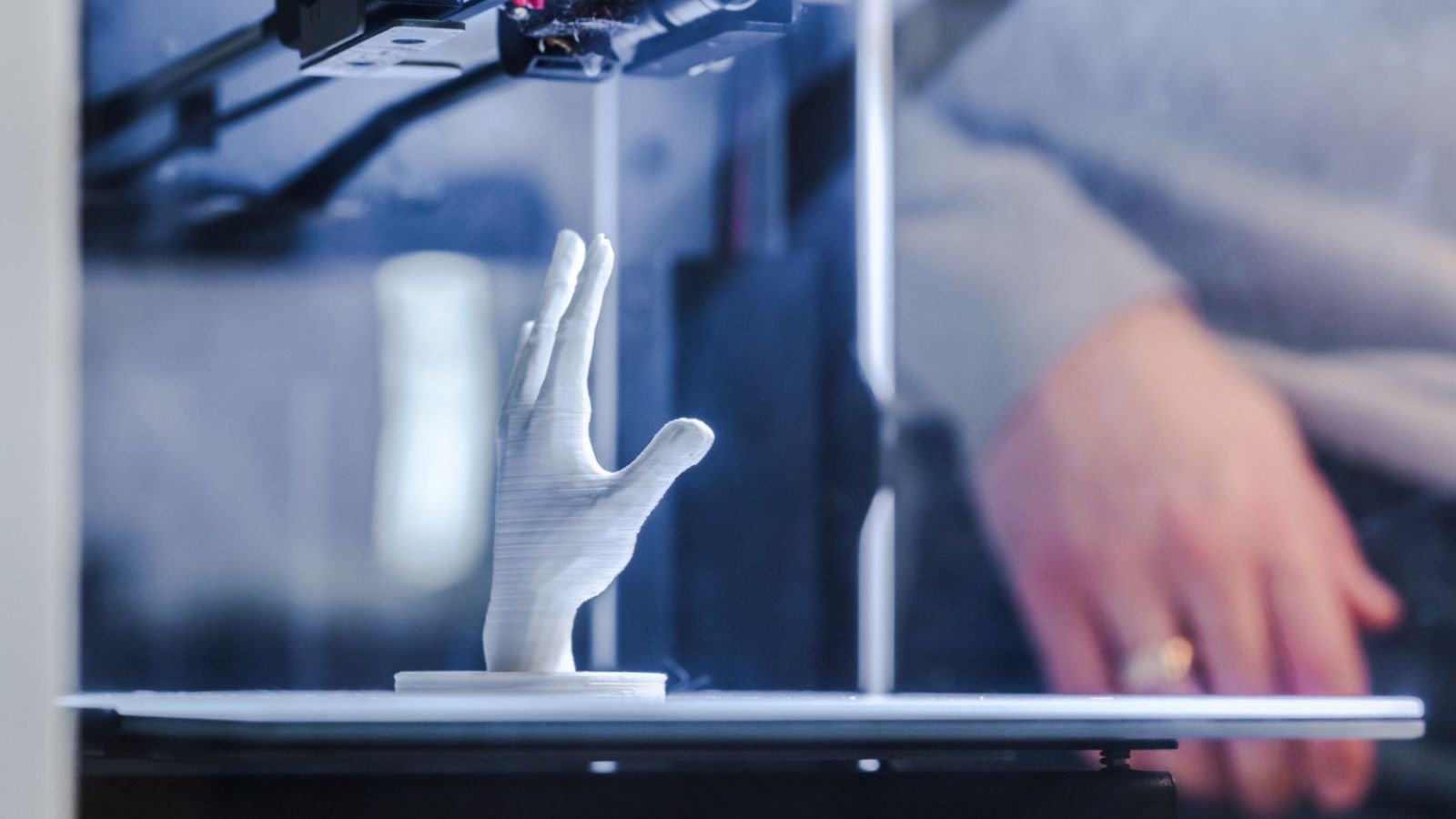

A 3D bioprinting is a new technique of additive manufacturing which deals with live cells a biomaterial and/or growth factors, which form bioinks, to print tissue like structures which mimic organs and tissues not found in any place other than in human bodies.

Unlike traditional 3D printing which uses a plastic or metal material, bioprinting isn’t about printing things biological piece no oversized bioprinting is about. Working from digital blueprints based on medical images or computer-aided design (or CAD). It prints-with the printer creating a precise and detailed replica of construction with the bioinks-is used to create complex and functional tissue constructs.

In other words, 3D bioprinting allows scientists to “print life” – grow living tissues that one day can be used in medical research, drug screening and even organ transplantation.

How 3D Bioprinting Works?

The procedure of 3D bioprinting entails a number of steps in which sophisticated interactions have to be produced between biology and engineering:

1. Bioprinting (Design and Preparations)

Researchers first create a 3D model of the desired tissue or organ using imaging techniques such as MRI or CT scans. They then prepare biological inks, or bioinks, made from living cells mixed with biocompatible materials that provide structure and nourishment.

2. Bioprinting(Printing the Structure)

It works just like printer ink as the bioprinter is adding each layer of bioink on the basis of the digital structure. Some of the printing technologies applied include: Extrusion-based printing InkJet /Bioprinting and Laser helped bioprinting.

3. Post-Bioprinting Processing (Maturation and Culturing)

After the printing, the tissue structure is moved to a bio-reactor, or incubator, where it will be incubated in order to provide the best conditions for the growth and maturity of cells that make up the structure of the tissue. Eventually, the cells begin to organize, send signals to each to make the natural function of the tissue.

This process is not unlike how human organs expand and divulge – with the promise of replacing contemporary methods of organ donation as well as complicated forms of curative in the medicinal field.

Real life uses for 3D Bioprinting

Bioprinting in 3D has a virtual unlimited number of applications on the pharmaceutical, research and manufacturing industries:

1. Regenerative Medicine

The production of tissues and organs for transplant is one of the most promising applications of 3D bioprinting. Scientists are trying to print working organs like livers, kidneys and hearts to curb the under-abundant organ receptors.

2. Pharmaceutical Testing

Due to the resource-involved and inability to conduct animal testing can use the bioprinted human tissues to evaluate the efficacy and toxicity of medication in a secure way. This way is more fast, ethical and make more precise results.

3. Cancer Research

Researchers use 3D bioprinted tumor models to study how cancer affects the body in realistic environments. These 3D models replicate real conditions better than 2D models, allowing researchers to interact with cancer cells more effectively and develop more accurate treatments for patients.

4. Application Skin Care

Three-dimensional (3D) bioprinting also creates artificial skin for burn patients and for cosmetic testing. Bioengineered tissues in the printed skin help accelerate healing and reduce the need for donor grafts.

5. Orthopedic Solutions and Dental Solutions

Bone and cartilage structures could be custom created and bio-printed to allow an injured body to be repaired and used to help improve the appearance of a misaligned face and orthopedic treatment.

Advantages of 3d Bioprinting in India

The recent popularity around the adoption of 3D bioprinting has seen the following advantages to the Indian healthcare, as well as the biotechnology ecosystem:

1. Personalized Medicine

Personalized treatments and less complications by means of 3D bioprinting to patient-specific tissues and implants and rational design with respect to their personal anatomy.

2. Cost-Effective Research

Compared to the traditional research and drug testing methods, the time as well as the cost be controlled by bioprinting is very ideal for the cost friendly healthcare scenario in India.

3. Increased Self-Sufficiency on Imports

As small start ups have begun working on indigenous bio-printers and bio-inks India can reduce the dependency on foreign technology and adopt the indigenous innovation.

4. Alternative to Animal Testing by Humans

Bioprinted tissues in organ tubes have already found use as a less cruel and far better as the scientific perspective form to get animal testing in pharmaceutical and cosmetic industries.

5. Promotion of Education & Training

Bioprinting courses/ training programs are being introduced and are being offered in universities and medical institutes as there will be a new generation of Bioengineers & researchers.

Conclusion

3D bioprinting marks a major leap in biomedical innovation. It has the potential to save lives, accelerate research, and transform the way medicine is practiced.

In India, this technology is more than just a scientific advancement. It offers a solution to critical healthcare challenges such as the shortage, availability, and affordability of organs.

Collaborations among startups, researchers, and policymakers are already taking shape. With these efforts, India is steadily moving toward becoming a global leader in the bioprinting revolution.

The road ahead may be complex, but the goal, a future where human organs and tissues can be printed on demand, is closer than ever.

In the coming years, 3D bioprinting will move from research labs to hospitals. It will bring personalized, ethical, and affordable medical solutions to millions, truly redefining healthcare innovation in India.

Also Read: Artificial Intelligence: Definition And Opportunities For Businesses